Choguy03

Well-Known Member

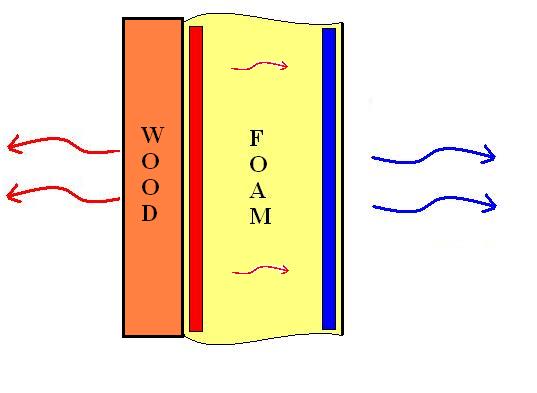

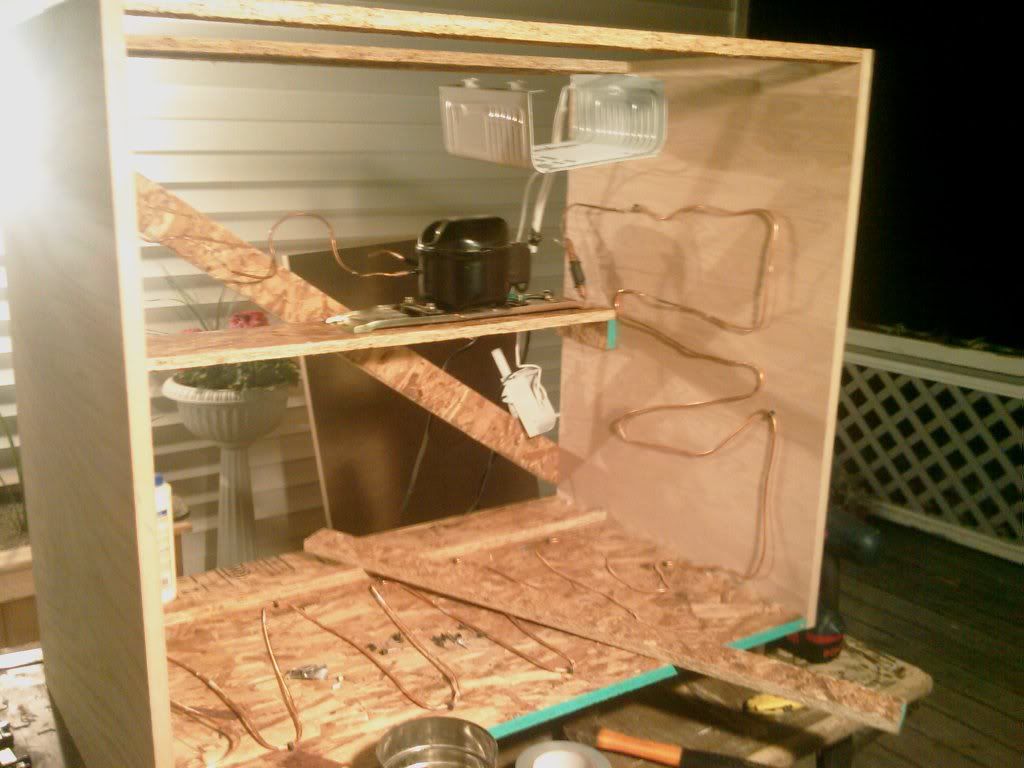

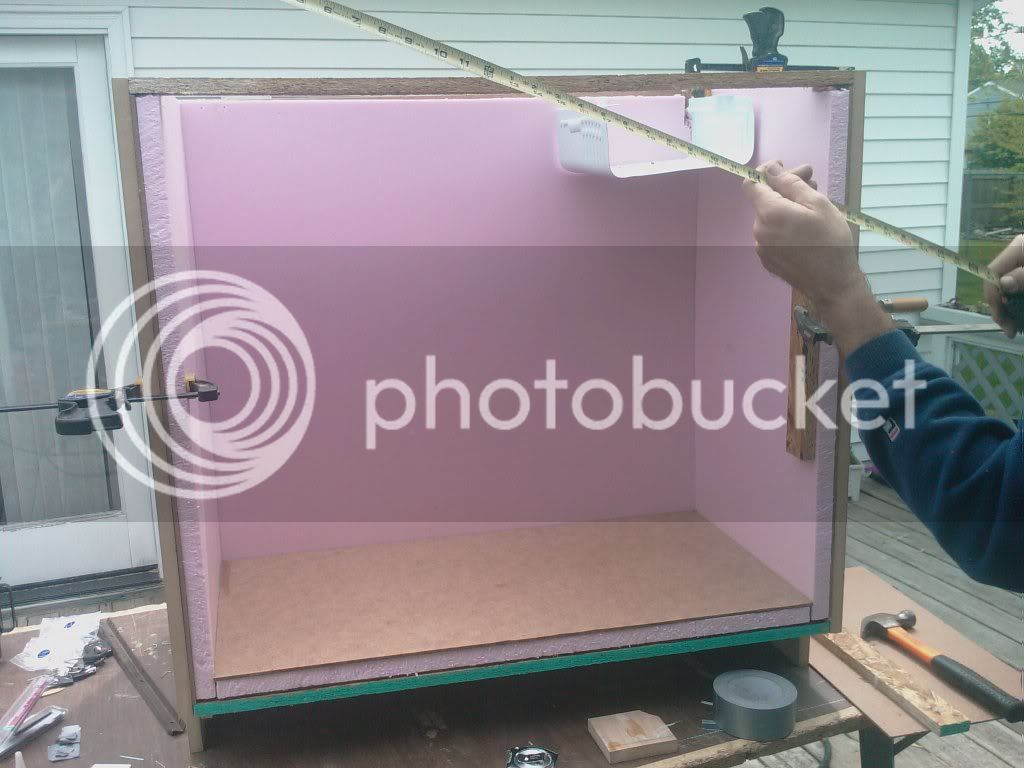

Well, here are a few pics from the almost finished product. I will be putting doors on this weekend. I used 3/4" oak mdf and then solid oak for the front. There is 1" foam board all around and there will be some on the door as well as some weather stripping to prevent any leaking.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)