eimar

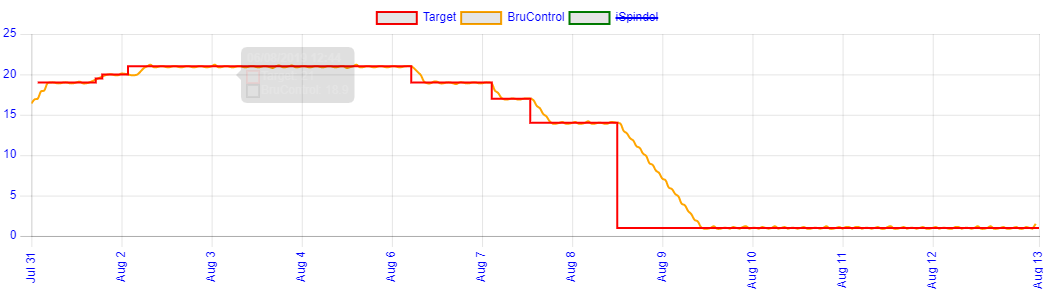

Brasserie Montfort No NEIPA brewed here

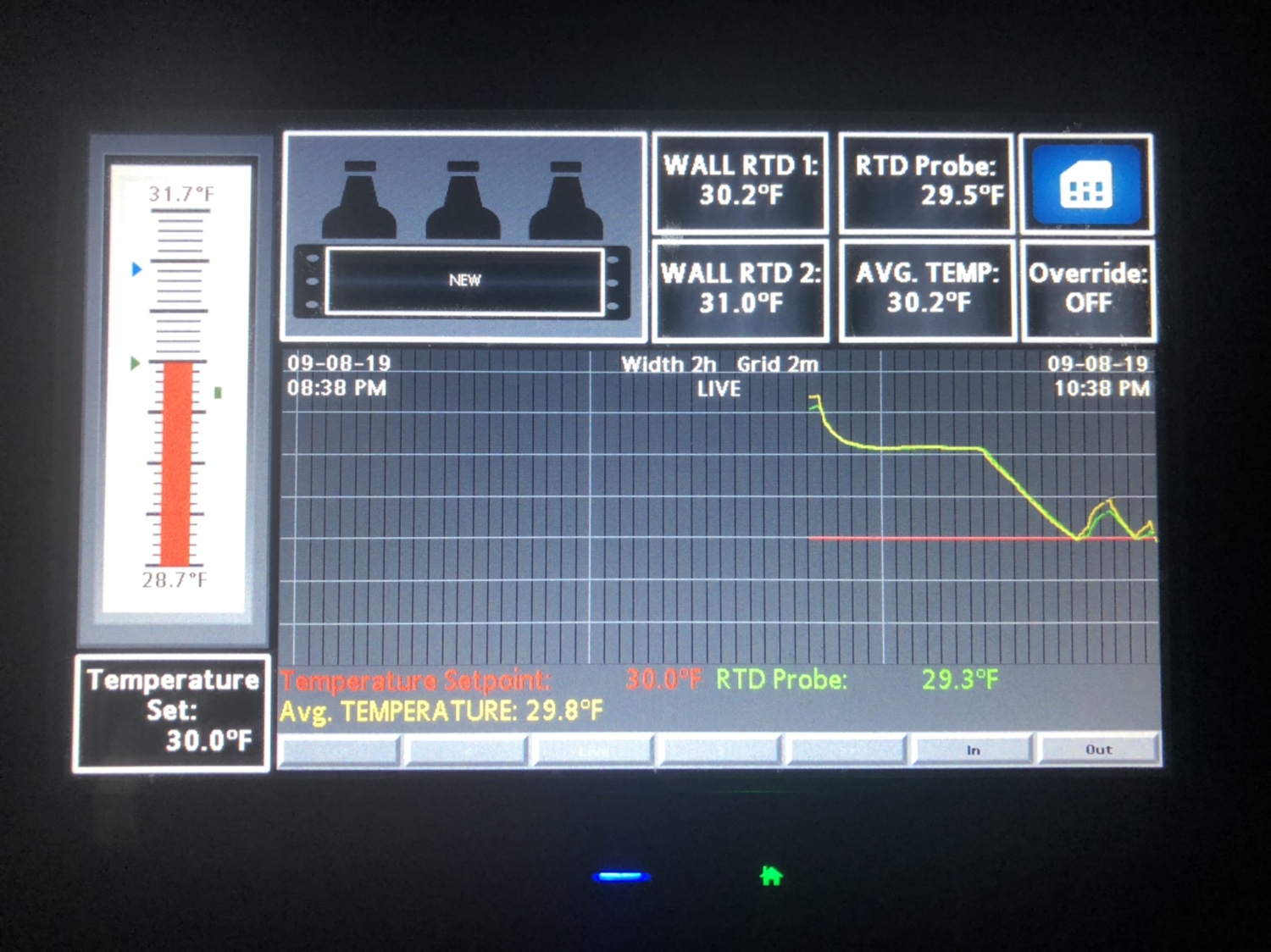

The sensor is a onewire DS18B20 , in a thermowell , connected to an ESP32

1) what is a good sampling rate: every 10 seconds ?

2) How long should the compressor stay off before being turned on again ?

3) Should I average several temperatures readings so the system won't turn on-off constantly ?

4) The temperature will vary between a setpoint and setpoint-delta . What is an acceptable value for delta ? 2 degrees celsius ?

My plan for the next step will be to use a PID algorithm ( right now I'm learning about the subject )

Jacques

1) what is a good sampling rate: every 10 seconds ?

2) How long should the compressor stay off before being turned on again ?

3) Should I average several temperatures readings so the system won't turn on-off constantly ?

4) The temperature will vary between a setpoint and setpoint-delta . What is an acceptable value for delta ? 2 degrees celsius ?

My plan for the next step will be to use a PID algorithm ( right now I'm learning about the subject )

Jacques