Is it time? It might be time. Time for something new in the world of BrewPi Arduino. Thanks to

@CadiBrewer for putting up with my crazy ideas, a new shield is born!

This is v1.3, code named: "The One Shield." I can't see where we can do anything different with the Arduino Uno. Perhaps most significantly, this shield provides hardware support for an

I2C display (there's important information about this below). There are other improvements which I think you guys are gonna dig.

BrewPi Arduino Uno Shield v1.3 (I2C/RevC) Changelog:

- (NEW) Four-pin I2C header. No more having to use that 16-pin ribbon! A mere 4 wires to connect your display. (Yes, the previous parallel LCD is supported as well.)

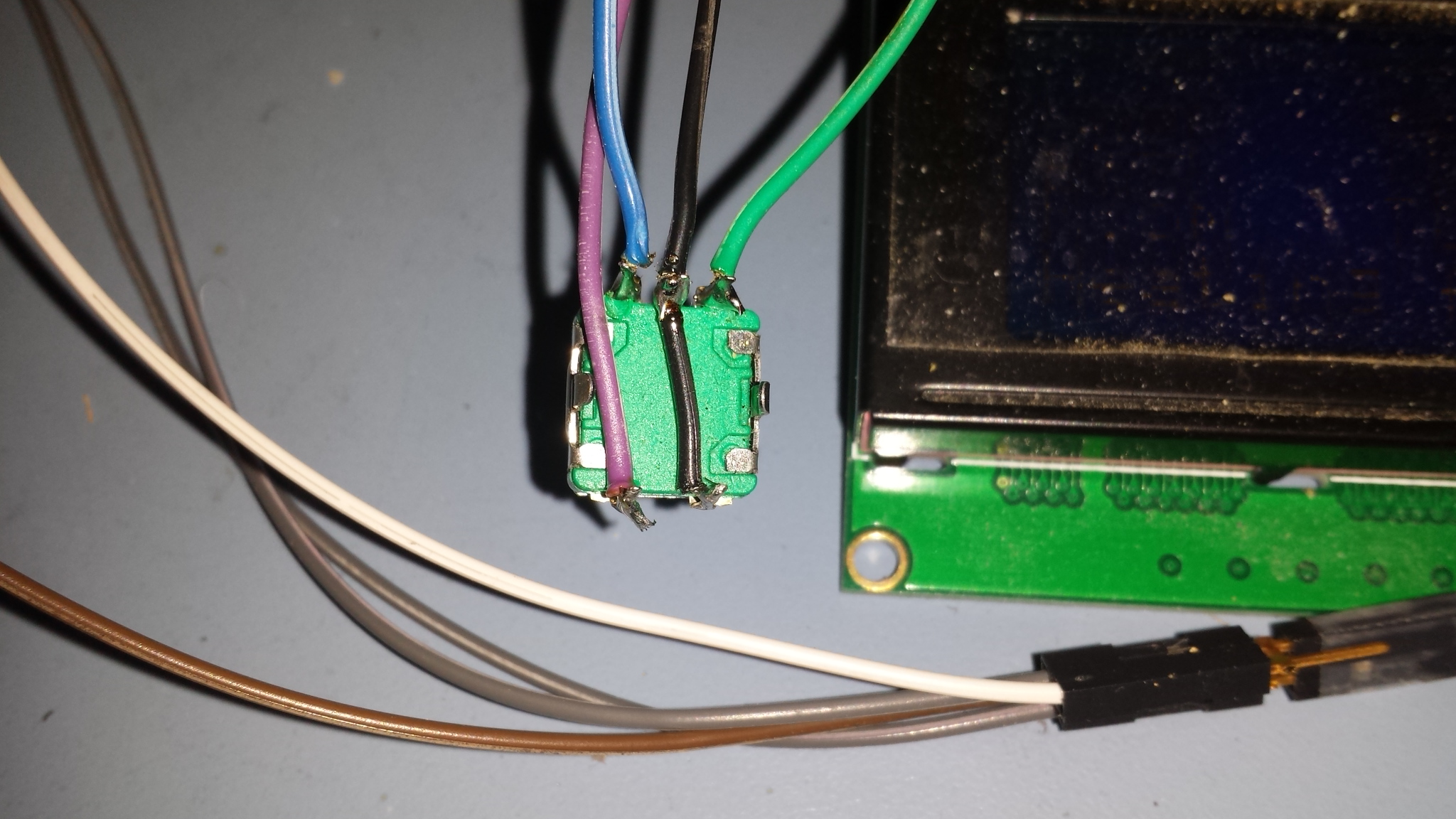

- (NEW) Rotary encoder header - No more having to figure out which Arduino header pins to use! There's also a rotary encoder breakout (thanks @gromitdj!) to make that easier to wire up.

- (CHANGE) LED headers - The old headers were one pin each for heat and cool, connected to a pull-up resistor. That worked fine with "normal" setups, but the wiring was not straightforward for what I call "mere mortals." And, if you used non-inverted outputs for heat and cool (such as with SRs) you found yourself in a strange position. These headers are three-pin: VCC <-> D5/6 <-> GND. This means if you are using "normal" inverted outputs, you connect your LEDs to VCC and the center pin for either LED. If you are using non-inverted outputs, you connect the LEDs to GND and the center pin for either LED.

- (CHANGE) Relays: This change re-orders the pins to match the typical relay headers.

- (NEW) OneWire Selection: One each three-pin header to switch between A0 or A4 for the One-Wire bus. You must use A0 if you are using I2C. Not sure why Elco ever used A4 but that's one of the hard-wired I2C pins for the Arduino so a chance was necessary.

- (CHANGE) Power: Version 1.2 split the power for the LCD and used the ICSP header to power the LCD backlight to reduce LCD scrambling. By all accounts that had no impact. On some Arduino clones (as well as the combo ESP8266/ATmega328P boards) have the ICSP header in a different place, which ended up requiring jumpers to apply power to the LCD, and/or creating a shorting point with the pins hitting an unexpected place on the controller board. This has been re-combined with the power and ground points looped together to form a single larger bus. In addition, from v0.2.11 of the Arduino firmware, there is a timer which resets the LCD display every 180 seconds to get rid of any scrambling.

- (NEW) Break-Out Board support: An RJ45 to allow for a remote break-out board. This uses an Ethernet cable (which is straight-through) as opposed to the smaller RJ11 (telephone cord) because phone cords are cross-over by default. The pin-out supports @Thorrak's original breakout boards, however support for remotely placing the heat/cool relays is also included. A breakout board supporting all of this is in development:

- Pin 1 - Unused

- Pin 2 - Unused

- Pin 3 - VCC

- Pin 4 - OneWire Data (A4 or A0)

- Pin 5 - GND

- Pin 6 - Door (D4)

- Pin 7 - Cool (D5)

- Pin 8 - Heat (D6)

- (NEW) Door pins: The original Arduino firmware has support for a contact switch which detects when the door is open. I don't know of many folks using this but adding two pins for that was easy enough since we already put it on the RJ45.

- (NEW) Alarm: The original firmware has VERY basic support for an alarm (piezo speaker). Right now, it only beeps when the Arduino resets but maybe we can do something more with it later.

- (CHANGE) Parallel LCD header: Even though the old header was 16-pins, we only used 12 of them. Using a straight 16 was simpler and kept people form screwing things up too bad but we needed the room. So, the parallel LCD header is now split into two 6-pin headers. This does give the benefit of making this connection much easier to route as bending two 6-wire ribbons is a lot easier than a 16-wire one.

- (NEW) LCD Backlight always-on: If one used the v1.2 board with no rotary encoder or at least a switch, the LCD would time-out and not be able to be turned back on. Added R13 to keep the backlight always-on in those cases. To make use of this functionality, REMOVE R12 and ADD R13.

If you want to use the I2C there are two important things you need to keep in mind!

- I2C support is a separate firmware image and only available in version 0.2.12. As of right now (6/1/19) this is a beta image, but I should be ready to release it soon. Firmware 0.2.12 requires BrewPi Scripts/WWW v0.5.2.1 which is currently in the Devel branch.

- You MUST select "A0" on the One-Wire selector.

When configured for I2C this is technically a new shield definition (I2C). When configured for the parallel LCD it works as an updated RevC.

Here's some PCB porn:

View attachment 629357 View attachment 629358

I have not yet uploaded the Eagle files to the BrewPi Remix website, but if you want to get a jump on things, get some board quickly (but maybe for a few extra bucks); I've

uploaded the files to OshPark (hence the purple board.) The BOM is there as well, including a link to a

BOM on Mouser which contains most of the parts needed.

This board should rightfully be considered an Alpha release, since none exist in the wild yet. Three people have reviewed the design however, and it builds on a successful predecessor for the more complicated circuits. I have the boards on order, should be assembling next weekend. I was way too excited not to share in this thread, however. As soon as they are tested, I'll make a release post on the Mega Thread.

As with most things related to electronics on this project, a HUGE thanks to

@day_trippr for his original design, his assistance which was given to

@CadiBrewer for versions 1.1 and 1.2, and for answering my stupid questions finalizing v1.3.