estricklin

Well-Known Member

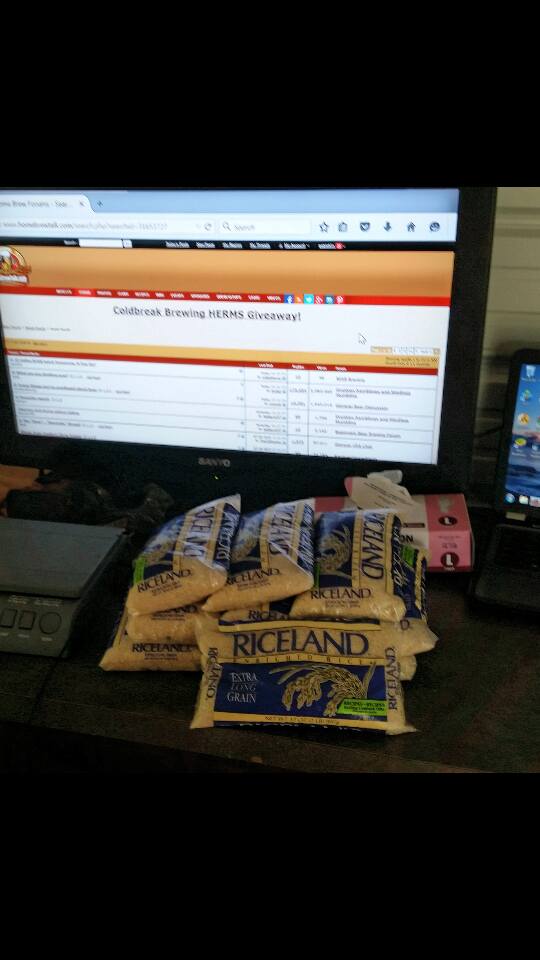

Ok so I am going to brew a 25 Gallon batch of American Lite Lager tomorrow, using a bag I purchased from wilserbrewer. The grain bill includes 40 lbs of 6 row, and 18 lbs of long grain rice which I will cook ahead of time.

My pot only holds 25 gallons, so this may sound like a stretch, but my plan is to top back up after the boil with enough water to equal the 25 gallons.

One of my main concerns is calculating my mash volume/temperature. I would ideally be doing a protein rest also. I'm not sure how much space 40 lbs of grain and 18 lbs of rice is going to take up, so I have no idea how much water to heat up, or to what temperature. I was considering putting all the grain and cooked rice mixture into the bag, and just filling the pot with tap water until it's completely full, then lifting the bag out to heat it. Anyone know of any problems with letting grain sit for a while with room temp water in it. Don't think the time it would take to heat the mash water up to 135F or so (for a protein rest) before doing a real mash would cause it to sour. The water would be about 100-110 degrees if I had to guess because I was going to use 6 gallons of water to cook the rice with.

I think this may be one of those things where I'm just going to have to wing it and see what happens.

Also am thinking of using some halyard snaps to lift the bag with, so that the weight will be spread out.

Any thoughts are greatly appreciated!

My pot only holds 25 gallons, so this may sound like a stretch, but my plan is to top back up after the boil with enough water to equal the 25 gallons.

One of my main concerns is calculating my mash volume/temperature. I would ideally be doing a protein rest also. I'm not sure how much space 40 lbs of grain and 18 lbs of rice is going to take up, so I have no idea how much water to heat up, or to what temperature. I was considering putting all the grain and cooked rice mixture into the bag, and just filling the pot with tap water until it's completely full, then lifting the bag out to heat it. Anyone know of any problems with letting grain sit for a while with room temp water in it. Don't think the time it would take to heat the mash water up to 135F or so (for a protein rest) before doing a real mash would cause it to sour. The water would be about 100-110 degrees if I had to guess because I was going to use 6 gallons of water to cook the rice with.

I think this may be one of those things where I'm just going to have to wing it and see what happens.

Also am thinking of using some halyard snaps to lift the bag with, so that the weight will be spread out.

Any thoughts are greatly appreciated!