BeardedBrews

Well-Known Member

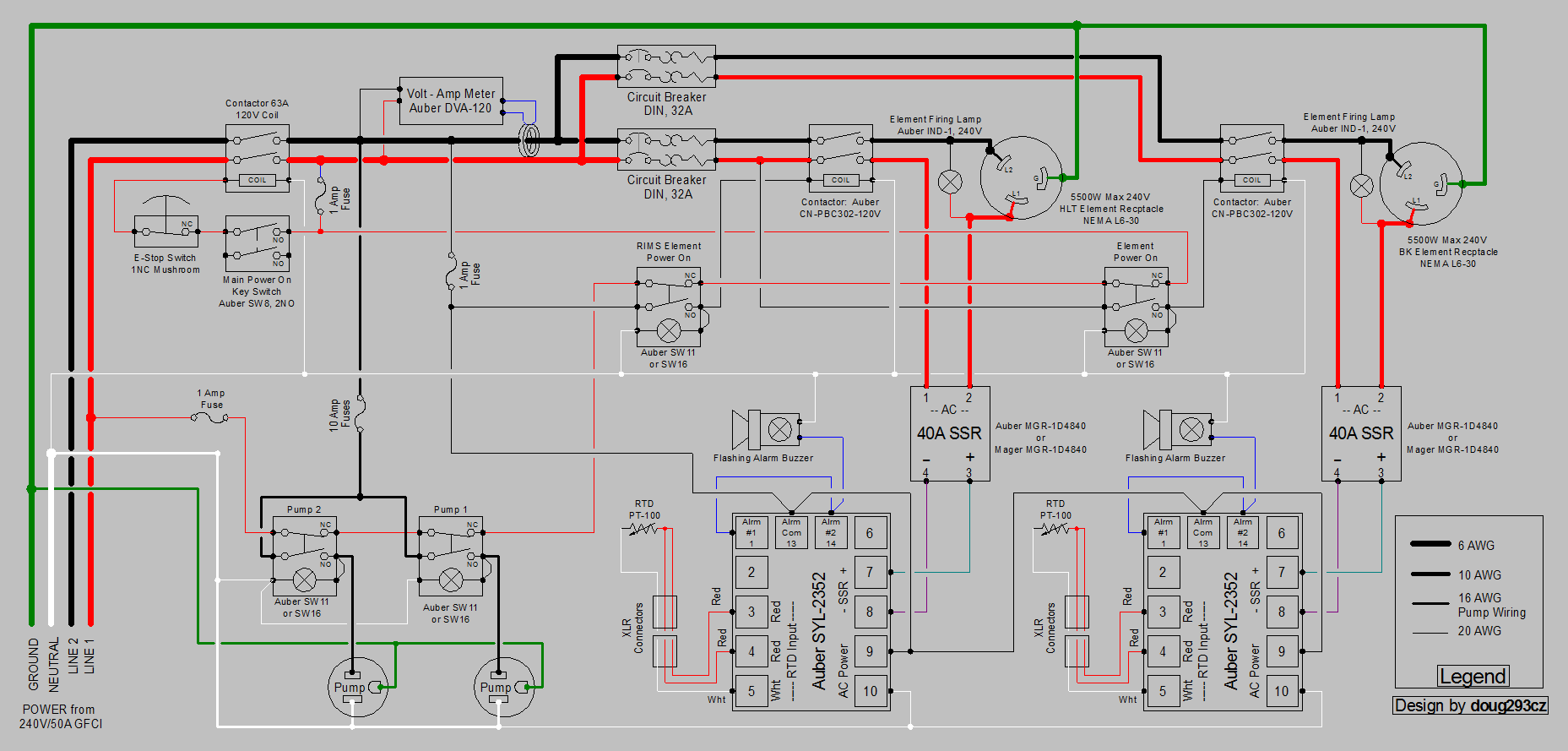

After delaying a bit to make sure I knew what I wanted medium-long term from my controller I have settled on a feature set pretty similar to the commercial units but opted for some budget components to reduce cost where appropriate while maintaining aesthetics and safety.

https://photos.app.goo.gl/C7XSvRyDQks8ZZvN7

Some highlights:

I went with a Bud Industries 12x8x5 box NBF-32016 and am very happy with the size for this application. It cuts easily and still feels very durable and secure. I opted to buy the metal backplate which also simplified installation.

I used a generic Uxcell aluminum heat sink that fit incredibly well on the box. It was a simple task to drill pilot holes and use self tapping screws to secure the ssr. Uxcell a14111400ux0256

I put too many terminal strips in. There is no real penalty for this, just didn’t use all the posts.

I like the rotary switches and lights. The parts are slightly more expensive vs a basic light switch, but the industrial feel is immensely satisfying.

Auber EZ Boil is amazing. Couldn’t be happier with the ease of use and reliability and I would recommend to anyone.

I did not use a disconnect in the controller for the power input or the element cord. The box is mounted to the wall and I can think of no reason to remove these cables. This saves space in the box and considerable cost.

I will be updating the RTD to a kettle mount option using a very high quality option from eBay. Thanks for the tip Auggie. https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/232587883318

I initially used a Fotek 40amp SSR and had odd sticking issues. Replaced with a proper Crydom which works great. I broke open the Fotek and discovered they were using a 12amp triac in the 40amp ssr which explained the performance problems.

I’m pleased with the results and satisfied with the upgrade cost vs my old ammo can.

https://photos.app.goo.gl/C7XSvRyDQks8ZZvN7

Some highlights:

I went with a Bud Industries 12x8x5 box NBF-32016 and am very happy with the size for this application. It cuts easily and still feels very durable and secure. I opted to buy the metal backplate which also simplified installation.

I used a generic Uxcell aluminum heat sink that fit incredibly well on the box. It was a simple task to drill pilot holes and use self tapping screws to secure the ssr. Uxcell a14111400ux0256

I put too many terminal strips in. There is no real penalty for this, just didn’t use all the posts.

I like the rotary switches and lights. The parts are slightly more expensive vs a basic light switch, but the industrial feel is immensely satisfying.

Auber EZ Boil is amazing. Couldn’t be happier with the ease of use and reliability and I would recommend to anyone.

I did not use a disconnect in the controller for the power input or the element cord. The box is mounted to the wall and I can think of no reason to remove these cables. This saves space in the box and considerable cost.

I will be updating the RTD to a kettle mount option using a very high quality option from eBay. Thanks for the tip Auggie. https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.com/ulk/itm/232587883318

I initially used a Fotek 40amp SSR and had odd sticking issues. Replaced with a proper Crydom which works great. I broke open the Fotek and discovered they were using a 12amp triac in the 40amp ssr which explained the performance problems.

I’m pleased with the results and satisfied with the upgrade cost vs my old ammo can.