At least two batches taste great at bottling day and develop "off flavours" after 2 week of bottle conditioning.

I brewed pinapple ipa and raspberry philly sour.

All tasted great from the FV. Added fruit in the end of fermentation. At bottling day both tasted fine. After 5 days in bottles i open up smallest bottle of IPA and taste was great but little undercarbed as expected. After extra week i open up next bottle and it had lost all its hop profile and pinapple flavour. It has little bit of metallic taste maybe even tiny bit sour and kind of sweeter than before(i tought it was oxidized but only sweetnes came probably bc of oxidation of Dryhopped beer).

Philly sour beer tasted great but it might be that i wasnt able to taste that mild off flavour behind its own sourness. It had great raspberry flavour so maybe it wasnt infected or lower ph protected against infection?

Both were bottled same day. First i bottled pineapple ipa and then raspberry sour.

So knowing that i have possible risk of infection i took EXTRA measures before bottling my next batch. (Mango IPA wich i had brewed 2 times sucsessfully before. But now made with more mango and more DH)

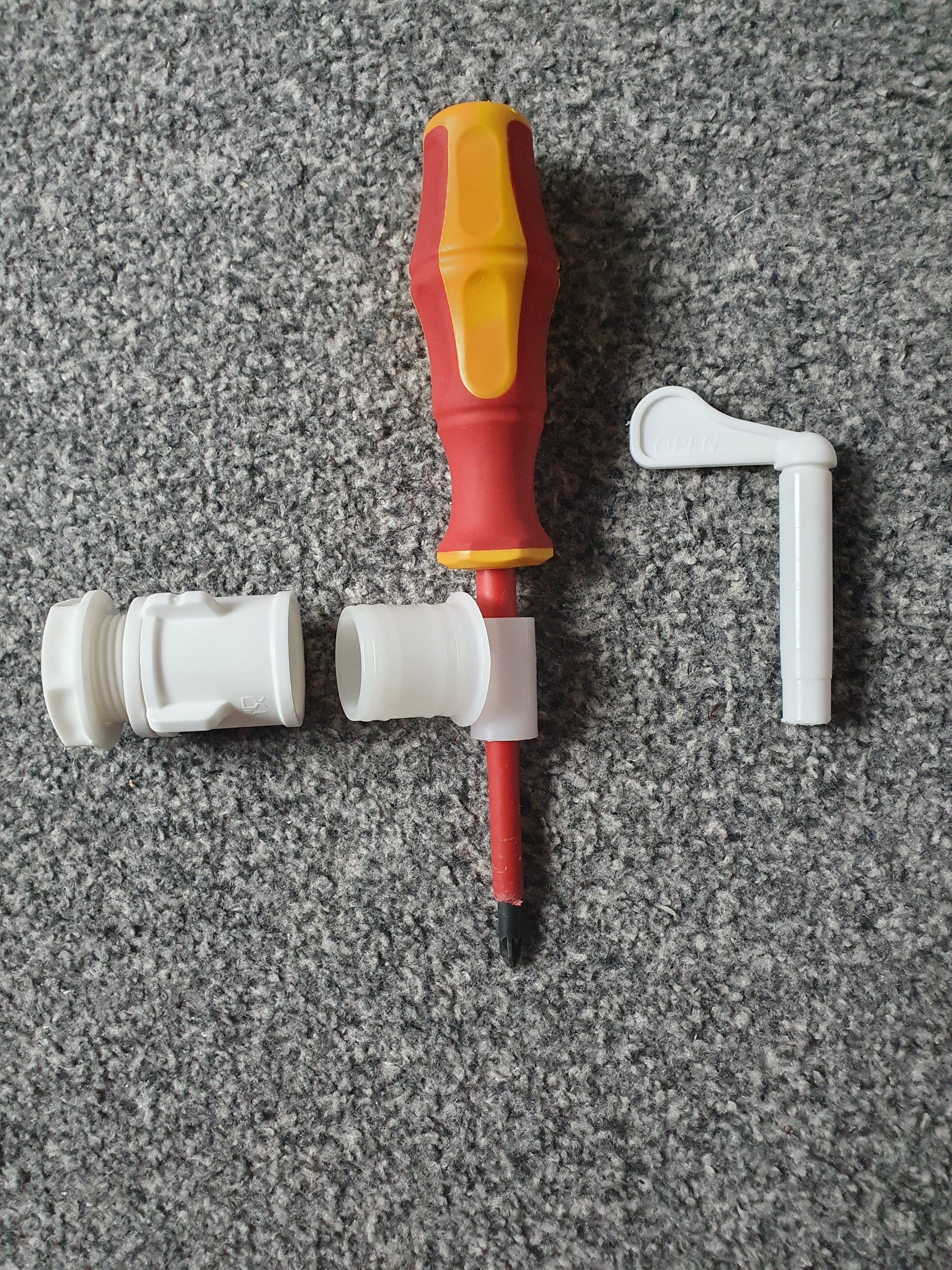

Afraid of infection I Soaked ALL my gear and bottles in hot VWP cleaner. Rinsed multible times. Then soaked bottles in starsan solution. I had bought new bottling bucket and autosiphon wich i also cleaned.

Added few grams of ascorbic acid into priming solution. Racked from the FV to the new bottling bucket with new siphon. And bottled with the siphon as usual but left almost no headspace to have less O2. Beer tasted exrteamly good at bottling day. Out of this world mango aroma and flavour, i was so happy.... Now after 2w in bottles and 5days in fridge. No mango and same kind of off flavour as with pineapple ipa. But no sweetness.

I just bottled my nectaron, citra, sabro Neipa 2 days ago with same gear and i am afraid it will turn out as bad even tho it was also great at bottling day.

I need to bottle my west coast ipa tommorow... but i am losing hope. And dont know what to do.

I wanted to have head start this year. Having brewed 6 beers.(Bottled 5) but now 2 going to waste and if i end up eventually dumping 4 of them i am going crazy

I brewed pinapple ipa and raspberry philly sour.

All tasted great from the FV. Added fruit in the end of fermentation. At bottling day both tasted fine. After 5 days in bottles i open up smallest bottle of IPA and taste was great but little undercarbed as expected. After extra week i open up next bottle and it had lost all its hop profile and pinapple flavour. It has little bit of metallic taste maybe even tiny bit sour and kind of sweeter than before(i tought it was oxidized but only sweetnes came probably bc of oxidation of Dryhopped beer).

Philly sour beer tasted great but it might be that i wasnt able to taste that mild off flavour behind its own sourness. It had great raspberry flavour so maybe it wasnt infected or lower ph protected against infection?

Both were bottled same day. First i bottled pineapple ipa and then raspberry sour.

So knowing that i have possible risk of infection i took EXTRA measures before bottling my next batch. (Mango IPA wich i had brewed 2 times sucsessfully before. But now made with more mango and more DH)

Afraid of infection I Soaked ALL my gear and bottles in hot VWP cleaner. Rinsed multible times. Then soaked bottles in starsan solution. I had bought new bottling bucket and autosiphon wich i also cleaned.

Added few grams of ascorbic acid into priming solution. Racked from the FV to the new bottling bucket with new siphon. And bottled with the siphon as usual but left almost no headspace to have less O2. Beer tasted exrteamly good at bottling day. Out of this world mango aroma and flavour, i was so happy.... Now after 2w in bottles and 5days in fridge. No mango and same kind of off flavour as with pineapple ipa. But no sweetness.

I just bottled my nectaron, citra, sabro Neipa 2 days ago with same gear and i am afraid it will turn out as bad even tho it was also great at bottling day.

I need to bottle my west coast ipa tommorow... but i am losing hope. And dont know what to do.

I wanted to have head start this year. Having brewed 6 beers.(Bottled 5) but now 2 going to waste and if i end up eventually dumping 4 of them i am going crazy

Last edited: