RobbieOByrne

Well-Known Member

Well I broke down and went full Keg. Bottling is nice but not as cool as a keg and keg bottling. I'll list what I got;

2 - corny kegs (homebrew shop said GTG, tested, trusted)

1 - CO2 Regulator w/ attached tank reg bracket (I can adjust pressure on each tank, wanted this incase I go big)

1 - 5 pound CO2 tank.

1 - Giant cooler for drinking time, I don't have room for a kegerator. (From what I've read and been told that as long as I chill before using the kegs and I keep then under CO2 pressure they can sit at room temp for a while).

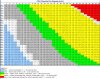

The plan was to slow carb my tanks, while I wait for my "forced" diet to end. So I set them to 10 pounds each. With a gradual increase in pressure to drinking levels a week or so before drinking time.

There was a leak and about 3 days ago I found my tanks pressure sitting at 0. Over the period of a week and a half god knows how much of the 5 pound tank I inhaled, luckily it was sitting right next to a open window the whole time.

I cannot tell if the leak is at the tank/reg connection, keg/reg connection or keg. I'm assuming its coming from the tank/reg connection, both tanks dropped to 0, which means its not a single tank problem to me... and I can't test for leaks until I fix problem 1.

Problem 1 - went to Praxair, for refill of CO2, instead of beverage grade... they decided to give me industrial grade. Imagine my surprise when the faint smell of spearmint filled the area when I purged my reg, luckily the dirty CO2 never hit my precious beer.

Question: Isn't it illegal to fill industrial CO2 into a clearly marked beverage CO2 tank? What's the process of removing industrial co2 and purifying my tank?

Problem 2 - My beer is possibly sitting with oxygen in the keg. I can only hope that there is enough CO2 in the keg to keep the oxygen out. But lets assume the worse.

Question: Oxygen on the beer does what? I assume it increase decay process?

Thanks for the advice and information!

2 - corny kegs (homebrew shop said GTG, tested, trusted)

1 - CO2 Regulator w/ attached tank reg bracket (I can adjust pressure on each tank, wanted this incase I go big)

1 - 5 pound CO2 tank.

1 - Giant cooler for drinking time, I don't have room for a kegerator. (From what I've read and been told that as long as I chill before using the kegs and I keep then under CO2 pressure they can sit at room temp for a while).

The plan was to slow carb my tanks, while I wait for my "forced" diet to end. So I set them to 10 pounds each. With a gradual increase in pressure to drinking levels a week or so before drinking time.

There was a leak and about 3 days ago I found my tanks pressure sitting at 0. Over the period of a week and a half god knows how much of the 5 pound tank I inhaled, luckily it was sitting right next to a open window the whole time.

I cannot tell if the leak is at the tank/reg connection, keg/reg connection or keg. I'm assuming its coming from the tank/reg connection, both tanks dropped to 0, which means its not a single tank problem to me... and I can't test for leaks until I fix problem 1.

Problem 1 - went to Praxair, for refill of CO2, instead of beverage grade... they decided to give me industrial grade. Imagine my surprise when the faint smell of spearmint filled the area when I purged my reg, luckily the dirty CO2 never hit my precious beer.

Question: Isn't it illegal to fill industrial CO2 into a clearly marked beverage CO2 tank? What's the process of removing industrial co2 and purifying my tank?

Problem 2 - My beer is possibly sitting with oxygen in the keg. I can only hope that there is enough CO2 in the keg to keep the oxygen out. But lets assume the worse.

Question: Oxygen on the beer does what? I assume it increase decay process?

Thanks for the advice and information!