It takes me a looong time and a lot of water to chill. (Cu EC) I want to make a CFC. How efficient are they? I want to be able to transfer from my BK thru the CFC to my carboys. and get the temp down to pitching temp. I have cold ground water (64-deg. summer). Will I be able to drop the temp to below 70 with one pass? In summer I could add an ice stage if needed. Thanks for the help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CFC ?

- Thread starter Gonefishin

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jack13

Well-Known Member

It takes me a looong time and a lot of water to chill. (Cu EC) I want to make a CFC. How efficient are they? I want to be able to transfer from my BK thru the CFC to my carboys. and get the temp down to pitching temp. I have cold ground water (64-deg. summer). Will I be able to drop the temp to below 70 with one pass? In summer I could add an ice stage if needed. Thanks for the help.

I recently used a CFC for the first time, and was shocked at how quickly it cooled. I recirculated it back into the kettle until it got down to high the 60's/70, but it happened so quickly I may not even bother doing that next time since it would make such a tiny difference if there is some hotter wort right in the beginning of the transfer.

The water was 62F that day, and my CFC is 25'.

Thanks Jack, I don''t want to recirc. my wort. Maybe I will incorporate my EC in an ice bath and run my cooling water thru that on the way to the CFC. Do you think that could get it done in one pass? At what flow rate(approx.) do you run the cooling water? Or, how much water does it take to chill? Thanks.

jack13

Well-Known Member

Thanks Jack, I don''t want to recirc. my wort. Maybe I will incorporate my EC in an ice bath and run my cooling water thru that on the way to the CFC. Do you think that could get it done in one pass? At what flow rate(approx.) do you run the cooling water? Or, how much water does it take to chill? Thanks.

Yes, the temp got down so quickly I only ended up recirculating a minute or so, so I'll probably not even bother next time and just do one pass. Plus the groundwater will probably be a bit lower than 62 next time.

I had the water going just below full blast. And lowering the flow did incresae the temperature of the wort coming out of the CFC. That's expected, but it was my first time so I thought maybe having the water a little slower was already cooling as quickly as possible, and having it higher was just wasting water. But no.

As for the wort flow, I had that pretty low and, sure enough, increasing it also increased the wort temp. I Felt like it took 15 minutes (maybe?) to transfer 5.5 gallons.

Lots of variables--temp of ground water, speed of water flow, speed of wort flow, temp of the wort (boiling or lower?), and efficiency of the CFC.

One of the keys as @jack13 notes is the flow of the water. Faster will cool better. The greater the difference in temps between the water and the wort, the greater the heat transfer. As the water warms moving through the chiller, that difference in temp declines, and chilling is less effective (at that point in the chiller). So fast water keeps the water colder, and chilling is more effective.

Typically brewers will throttle down the flow of the wort until it gets to the point where the exiting wort is the proper temperature. This means you need some sort of thermometer at the exit of the CFC to monitor that, and be able to adjust the flow.

Below is a pic of mine showing how I did it. The black caps cover the camlock fittings. I used a stainless T and a thermometer I had as a spare. BTW, mine is stainless, which is not as efficient as a copper CFC. I'm doing LODO stuff which is why the SS.

One of the keys as @jack13 notes is the flow of the water. Faster will cool better. The greater the difference in temps between the water and the wort, the greater the heat transfer. As the water warms moving through the chiller, that difference in temp declines, and chilling is less effective (at that point in the chiller). So fast water keeps the water colder, and chilling is more effective.

Typically brewers will throttle down the flow of the wort until it gets to the point where the exiting wort is the proper temperature. This means you need some sort of thermometer at the exit of the CFC to monitor that, and be able to adjust the flow.

Below is a pic of mine showing how I did it. The black caps cover the camlock fittings. I used a stainless T and a thermometer I had as a spare. BTW, mine is stainless, which is not as efficient as a copper CFC. I'm doing LODO stuff which is why the SS.

Thanks y'all. Mongoose, that's a great looking stainless setup. I like that thermometer.

I am planning to use a pump to adjust my outflow to regulate the temp. I saw a small filter on someones rig but can't find the post again. It was on the outflow off his brewpot to aid in reducing hop trub going thru his pump. Looked like it would work without much loss. What do y'all use? Something else I am considering is using O2 to push the last of my wort from my pump out to the fermenter. I am concerned I'll have a lot of wort lost between my pump and my fermenter. I'm going to have 20+feet of Cu in my CFC and I'll have about 15+' of tubing to my fermenters. I don't oxygenate anymore but it seems like I could just inject the O2 into the air port that would be for priming and when the BK is empty, just push it clear with some O2. I swear, the more I think about this stuff the more involved it keeps getting. Thanks for the input, even if it does keep adding to the overall system.

I am planning to use a pump to adjust my outflow to regulate the temp. I saw a small filter on someones rig but can't find the post again. It was on the outflow off his brewpot to aid in reducing hop trub going thru his pump. Looked like it would work without much loss. What do y'all use? Something else I am considering is using O2 to push the last of my wort from my pump out to the fermenter. I am concerned I'll have a lot of wort lost between my pump and my fermenter. I'm going to have 20+feet of Cu in my CFC and I'll have about 15+' of tubing to my fermenters. I don't oxygenate anymore but it seems like I could just inject the O2 into the air port that would be for priming and when the BK is empty, just push it clear with some O2. I swear, the more I think about this stuff the more involved it keeps getting. Thanks for the input, even if it does keep adding to the overall system.

I do two things. One is I whirlpool, which creates a trub cone in the middle of the kettle. The other is...I don't worry about it all that much. Before I bought my conical fermenter I used to just dump it all in the plastic fermenter, and I never could see any difference doing that versus straining it out.

I can't use an immersion chiller because I'm doing the steam catcher system to eliminate steam from the boil kettle going into the air of my garage, but I sure miss it. I have a Jaded Hydra and nothing is close to that as far as speed. But I'm trying to do LODO brewing techniques and copper is NG for that.

I can't use an immersion chiller because I'm doing the steam catcher system to eliminate steam from the boil kettle going into the air of my garage, but I sure miss it. I have a Jaded Hydra and nothing is close to that as far as speed. But I'm trying to do LODO brewing techniques and copper is NG for that.

So hop residue is not a concern for your pump? Any idea how much hops were in the brew in your pic? How long do you have to whirlpool to get the trub to the middle like that?

So hop residue is not a concern for your pump? Any idea how much hops were in the brew in your pic? How long do you have to whirlpool to get the trub to the middle like that?

Well, it hasn't been. I don't know how to whirlpool without that going through the pump. It's a Blichmann Riptide, has the magnetic impeller.

That pic is a little old; can't recall exactly what I had in that. Typically I'll have 3-5 ounces of hop pellets in the boil. I usually have it whirlpooling for a while, but I think you get most of what there is in just a couple minutes.

I've read of people whirlpooling by using a spoon to stir the wort really fast and then letting it settle.

I made my own CFC, 35' garden hose and copper pipe. I do 10g batches. I run pool water through the chiller with a HF fountain pump and recirculate wort until it gets below 100f (FL, my pool is almost 80 in the summer), this takes 30-45 min. When wort is below 100f, I put the fountain pump in a big cooler withwater and 25lb ice block. I turn down the wort flow until exit is near pitch temp and fill fermenters. I envy you guys with 50-60deg tap water.

I made my own CFC, 35' garden hose and copper pipe. I do 10g batches. I run pool water through the chiller with a HF fountain pump and recirculate wort until it gets below 100f (FL, my pool is almost 80 in the summer), this takes 30-45 min. When wort is below 100f, I put the fountain pump in a big cooler withwater and 25lb ice block. I turn down the wort flow until exit is near pitch temp and fill fermenters. I envy you guys with 50-60deg tap water.

Hey, my chilling water is 60F and I'm right around the corner from you! I know because I brewed this weekend and it was 62F. I use my pool!

It takes me a looong time and a lot of water to chill. (Cu EC) I want to make a CFC. How efficient are they? I want to be able to transfer from my BK thru the CFC to my carboys. and get the temp down to pitching temp. I have cold ground water (64-deg. summer). Will I be able to drop the temp to below 70 with one pass? In summer I could add an ice stage if needed. Thanks for the help.

I really like the one in the link below because it's really easy to clean. Just pop the tubes off the end and use the included brush to clean the pipes. Takes 1 minute and you get over crevice, no worries. All chillers will eventually clog - I've even clogged this one, once with massive pitch of hop pellets and other time a few weaks ago when a hop bud (leave hops) got stuck in there. Both times, took just a minute to clear it. I also dropped a picture of how I monitor the returning wort temperature.

Chiller Showdown: Blichmann Therminator vs JaDeD Brewing Cyclone

Hey, my chilling water is 60F and I'm right around the corner from you! I know because I brewed this weekend and it was 62F. I use my pool!

I was still at 70 last weekend.... What size submersible pump do you use? I don't remember what I have, but I feel like it's not enough. I was thinking of using a 1/3 hp sump pump

TechFanMD

Well-Known Member

I have about the same temp water as you an my cheap copper immersion chiller drops the temp down to 70 in less than 15 minutes......the key is keeping the wort moving. I am surprised your takes so long.

I was still at 70 last weekend.... What size submersible pump do you use? I don't remember what I have, but I feel like it's not enough. I was thinking of using a 1/3 hp sump pump

It's a spare pump I used to use for my fish tank. I moved on to a non-submersible larger one, and this one ended up in my brewing kit. Link below (was Mag Model 7, but I guess that company got bought). Moves water very well through the chiller I think.

Magnetic Drive Pump 7

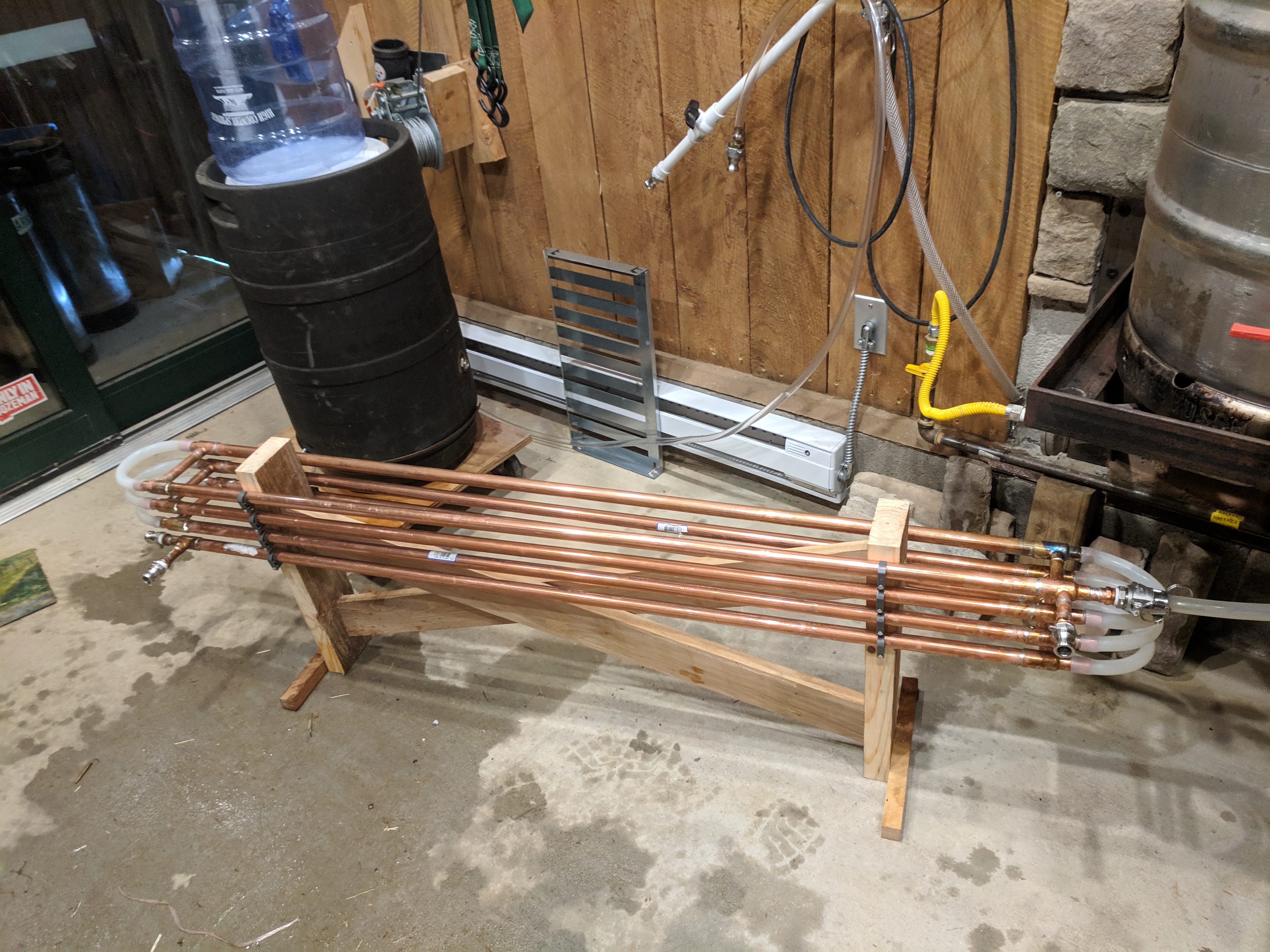

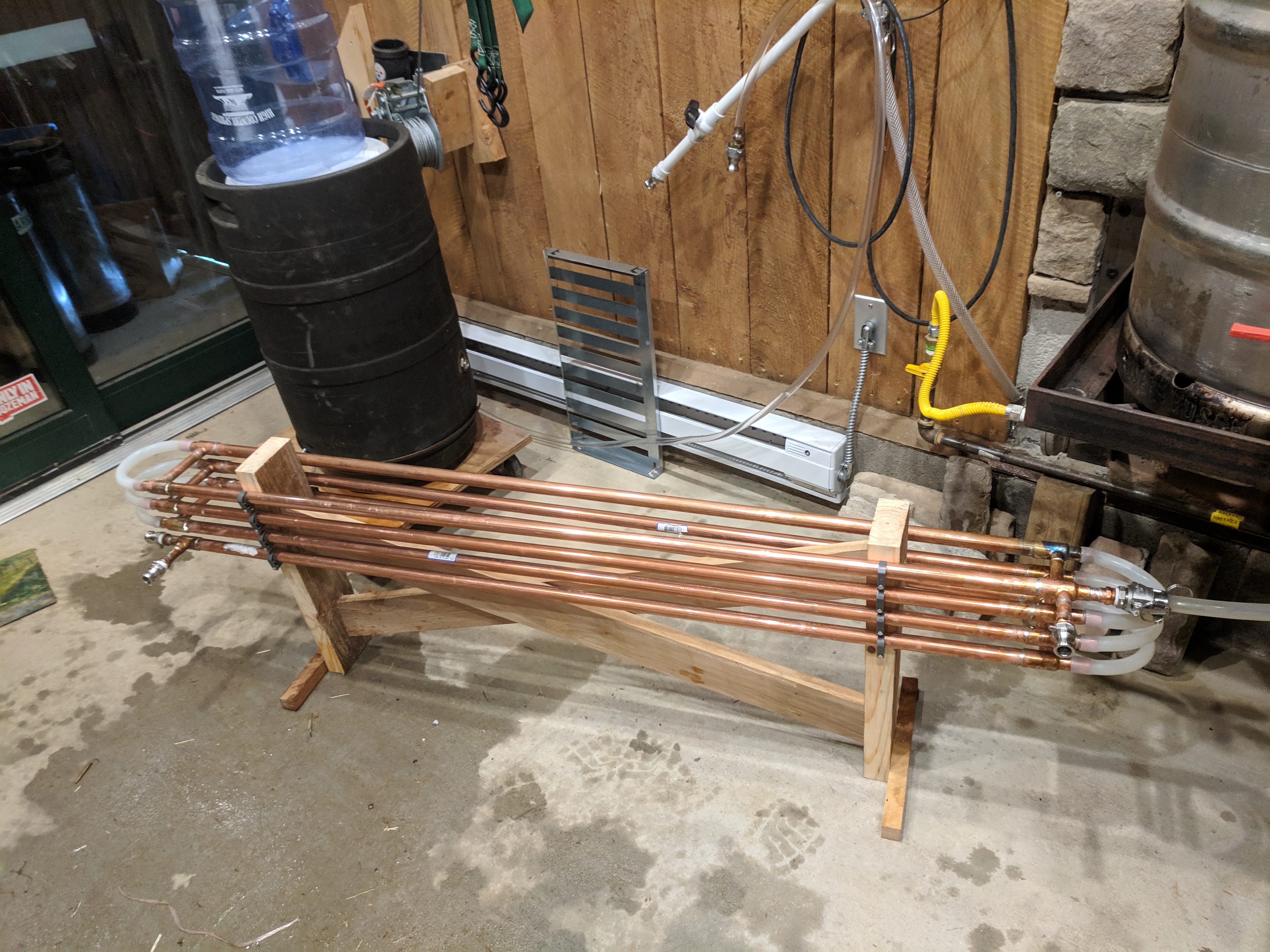

Well, its finally done and I took it for a test drive. I ran 12+gal. of boiling water through it. It took less than 15 min. and my water at the outlet was 69-deg. I ran about 13-gal. of ground water through it. After a 10-min. whirlpool step, the wort temp should be near or below 200-deg. so I may pick up a few min.'s. I am thrilled that this thing works as planned.

I used 35' of 1/2" Cu. inside and 3/4" Cu. outside. It is somewhat heavier than I thought it would be. And more expensive than I thought it would be. Here is a pic.

I used 35' of 1/2" Cu. inside and 3/4" Cu. outside. It is somewhat heavier than I thought it would be. And more expensive than I thought it would be. Here is a pic.

That's one big chiller - very impressive!

Looks like the hoses are slipped over tubing stubs - will the hoses stay in place without clamps?

Cheers!

Looks like the hoses are slipped over tubing stubs - will the hoses stay in place without clamps?

Cheers!

That was a concern of mine as well. The flow is low so very low pressure. They stayed right in place, not even a drip. I had seen this basic design in another thread but I bought a bunch of stainless clamps just in case.

I brewed the first batch using my CFC yesterday. 5-gal. to 68-deg. and 5-gal. to 67-deg..

I circulated for about 5-min. to sanitize prior to transfer. I whirlpooled with a sanitized paint stirrer after flame out which worked really well. I used approx. 11-gal. of ground water per batch to cool. After transfer, I ran the warmed chilling water through the pump and chiller to rinse. Then I added PBW to some of the water and circulated that for about 5 to 10-min. or so. Then rinsed again.

I have shaved at least an hour from my brew day. Probably more. I did not even have time to clean out my mash tun because chilling was sooo fast. Overall, I am very pleased with this build. It cost more to build and weighs more than I had anticipated but it does a great job.

I circulated for about 5-min. to sanitize prior to transfer. I whirlpooled with a sanitized paint stirrer after flame out which worked really well. I used approx. 11-gal. of ground water per batch to cool. After transfer, I ran the warmed chilling water through the pump and chiller to rinse. Then I added PBW to some of the water and circulated that for about 5 to 10-min. or so. Then rinsed again.

I have shaved at least an hour from my brew day. Probably more. I did not even have time to clean out my mash tun because chilling was sooo fast. Overall, I am very pleased with this build. It cost more to build and weighs more than I had anticipated but it does a great job.

Similar threads

- Replies

- 9

- Views

- 2K